What Factors Determine Which Material Is Best for Vessel Construction

Carbon steel is an alloy between carbon and iron. In the broad sense the term pressure vessel encompasses a wide range of unit heat exchangers reactors storage vessels columns separation vessels etc.

13 Commercial Used Bathroom Partitions 5 Years Warranty Ceplukan Commercial Bathroom Designs Commercial Bathroom Ideas Restroom Design

A preliminary analysis of the materials of construction for the reactor can be conducted after the reaction conditions have been specified.

. See also Mechanical Design of Heat Exchangers. Section VIII Division 1. Material size operating pressure process conditions.

A pressure vessel as a type of unit is one of the most important components in industrial and petrochemical process plants. An iron container holding sea water the fatigue life of the vessel if the pressure or temperature varies considerably variation of ductility with temperaturethe list goes on. The proper selection of materials to be used in a particular construction project depends on the following factors.

Maximum Allowable Working Pressure MAWP 4. Materials allowed for constructions are listed in Section II Part D and also in the code of construction eg. Finally the most important factor is that the availability of the material resource.

This availability decides the cost of the material. Determine Materials of Construction. Briefly describe the materials shortlisted based on the above properties.

So it is necessary to consider this factor as the major one in the selection of materials for the engineering purpose. What factors determine which material is best for vessel construction. At extreme conditions costly alloys may need to be used.

Site data for wind and seismic parameters 11. A great design may fail to be a profitable product if unable to find the most appropriate material combinations. Market conditions material and labor design class and rig specifications shipyard and the time of construction are the primary factors that impact newbuild costs.

Minimum Design Metal Temperature MDMT 5. Also known as mild steel carbon steel is one of the most commonly used engineering materials. Loads Load Combinations 12.

Charles E Thomas Rent Buy. Obviously there are many other factors that you should consider including corrosion of the vessel material eg. From the economical point of view the material should be easily available in nature.

The minimum temperature till which carbon steel vessel can work satisfactorily is -20F before it loses its ability to resist sudden shock. Gold is one of the most ductile metals but since we are considering from the point of view of ship construction the ductile materials use for this purpose include tin zinc lead copper etc. Carbon steel and stainless steels are some of the most common metals used in construction.

Brittle fracture is discussed in more detail in Module 4 Brittle Fracture. If the code of construction does not include a material listed in Section II D the material cannot be used with that code of construction. Service Process purpose description 6.

Process Technology Equipment and Systems 4th Edition Edit edition Solutions for Chapter 3 Problem 12RQ. The following material properties impact pressure vessel design. Aesthetic Reasons We all love to create beautiful structures of buildings roads bridges towers etc.

Aesthetics play an important role in choosing the right construction materials for many areas. Therefore climate is one of the determining factors in selecting specific construction materials for buildings. Grade 4 which has slightly higher trace levels of iron and oxygen has higher strength than Grade 2 but it is not suitable for welding and it is not covered by the PED or ASME Code.

Grade 2 is the material most commonly used for industrial equipment since it can be fabricated by welding and can be used to make vessels compliant to the PED ASME Code. Wave force on fixed moored vessel in beam sea Response spectrum analysis schematic Example of mooring line force spectra Example of vessel motion response spectra Vessel motion s a functio n of wave perio d an directio. Material selection is one of the foremost functions of effective engineering design as it determines the reliability of the design in terms of industrial and economical aspects.

In te rms of the fatigue crack initiation the appropriate parameters are the threshold stress intens ity factor range. Vessel standoff-force definition Surge and sway force and yaw moment due to a passingvessel. Ductility is essential for steels used in construction of reactor pressure vessels.

1 Provide a shortlist of materials suitable for use as construction of the pressure vessel based upon the major requirements as following. A wide range of construction materials is available. A closely related term is notch ductility and this gives a measure of the relative toughness of steel which is measured using impact test.

Carbon Steel Fairly economical and has wide temp range. So it is vital to know what the best materials for a particular design are. 2 Rank and index the materials in terms of the suitability and meeting the.

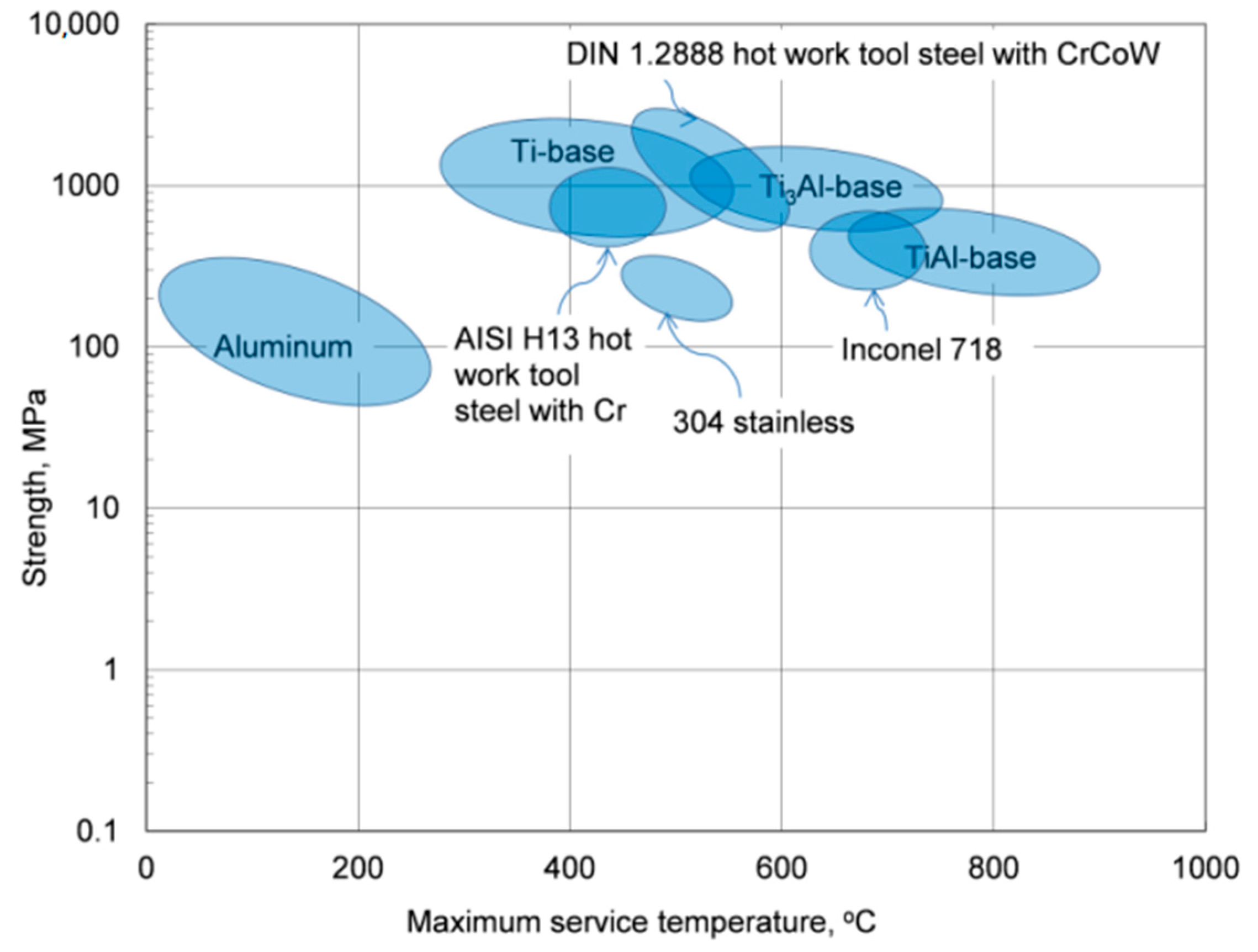

Factors Influencing Economy of a Building Material. Candidate materials are carbon steels low alloy steels and stainless st eels which interestingly are the materials that are used for pressure vessels. Particularly important in this analysis are the temperatures and pressures the process will run at.

A material consisting of two or more metals or a metal and a nonmetal What factors determine how thick a vessels walls should be. Ductility is required because the vessel is subjected to pressure and temperature stresses that must be carefully controlled to preclude brittle fracture. It is favored because it is relatively cheap and widely available.

Materials Selection and Design of a Pressure Vessel.

Choosing The Right Material For Your Pressure Vessel Honiron Manufacturing

New Materials To Make Ships More Sustainable And Less Noisy For Marine Life Research And Innovation

Materials Free Full Text Thermal Stability Of Aluminum Alloys Html

Corrosion Materials Inspectioneering

Water Faucet Is Also The Important Accessory Along With Other Things At Our Homes It Can Beautify The Interior Look Of Best Faucet Water Faucet Kitchen Faucet

Customized Tank Polishing Machine For Stainless Steel Stainless Steel Tanks Machining Metal Steel

Pipeline Drafter Job Ad And Description Template Free Pdf Google Docs Word Template Net Job Description Template Job Description Graphic Designer Job

Basic Ship Construction Properties Of Materials Used Bright Hub Engineering

What Exactly Is A Compression Washer Faucet Faucet Washer Sink

Pdf Scaffold Techniques And Designs In Tissue Engineering Functions And Purposes A Review

Static Equipment A Look Inside The How And Why Of Specification

American Estates 9 X 36 Saddle Wood Floors Kitchen Flooring Porcelain Wood Tile Wood Tile Floors

New Materials To Make Ships More Sustainable And Less Noisy For Marine Life Research And Innovation

Spray On Asbestos Insulation Mesothelioma Asbestos How To Find Out

40 Rustic Bamboo Interior Designs And Crafts House Window Design House Wall Design House Roof Design

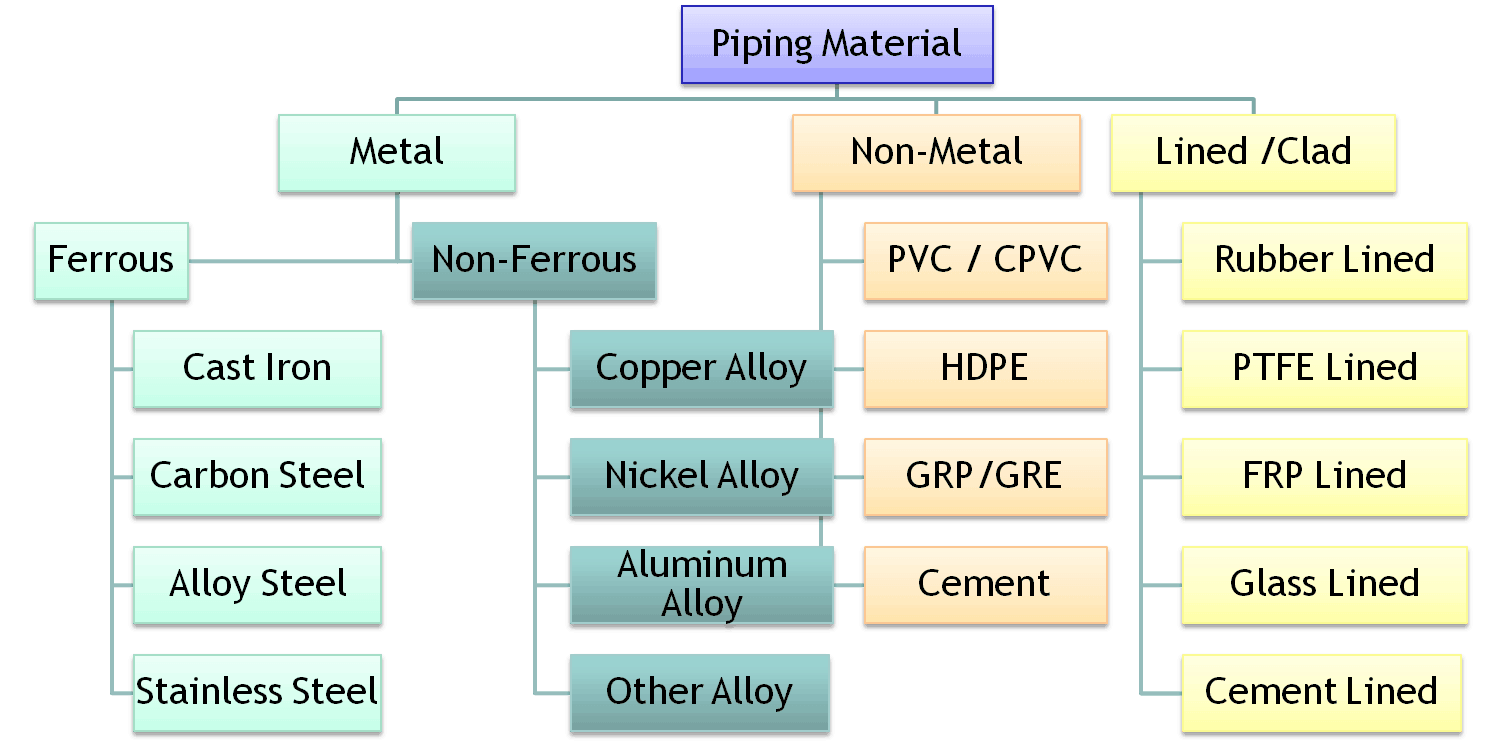

Pipe Material Types And Selection A Complete Guide

Exploring The Hull Material Used In Modern Boat Design Shm Blog

Comments

Post a Comment